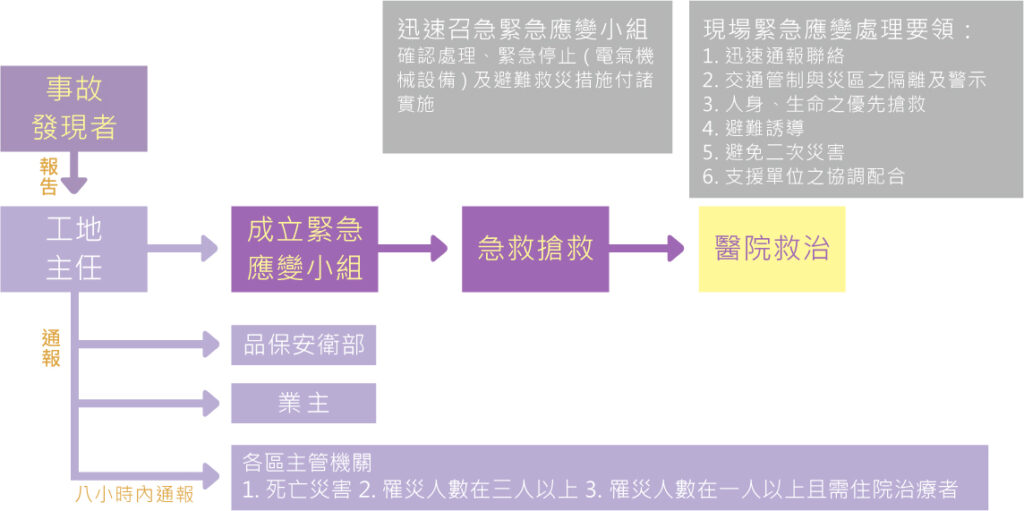

To reduce occupational accident risk, the company has established project site duty disaster prevention notification regulations as the basis for real-time monitoring of site conditions and emergency response to industrial safety incidents. When accidents occur, on-site personnel immediately notify the site supervisor, who then notifies the owner, occupational safety and health department, and relevant competent authorities, while activating emergency response teams to quickly initiate rescue and medical treatment procedures.

This notification and response process applies to all employees and engineering personnel at all project sites, ensuring incidents can be handled immediately with impacts minimized. Additionally, the occupational safety and health department regularly conducts site inspections, continuously tracking and supervising improvements to unsafe environments or high-risk behaviors, strengthening on-site occupational safety management.

Occupational Accident Investigation Process Flow Chart

Ruentex Engineering & Construction Disaster Classification and Reporting Procedure

| Disaster Classification Description of Situation Reporting Procedure | Description of Situation | Reporting Procedure |

|---|---|---|

| Minor Disasters | Minor Disasters Can be handled internally (including false alarms) or loss exceeding NT$10,000 Discovering personnel > Immediate notification to department supervisor > Within 30 minutes, report to Quality and Safety Department supervisor > Within 2 hours, report to the General Manager | Discovering personnel > Immediate notification to department supervisor > Within 30 minutes, report to Quality and Safety Department supervisor > Within 2 hours, report to the General Manager |

| Moderate Disasters | One or more individuals injured and requiring hospitalization or losses exceeding NT$100,000 | Personnel discovering incident > Immediately notify department supervisor > Report to Quality and Safety Department supervisor within 10 minutes > Report to the General Manager within 30 minutes |

| Severe Disasters | Media coverage, one or more fatalities, three or more injuries, or financial losses exceeding NT$300,000 | Severe Disasters Media coverage, one or more fatalities, three or more injuries, or financial losses exceeding NT$300,000 Personnel discovering incident > Immediately notify department supervisor > Report to Quality and Safety Department supervisor within 10 minutes > Report to the General Manager within 30 minutes > Report to the President within 1 hour |

Ruentex Materials Disaster Classification and Reporting Process

Ruentex Materials places utmost importance on occupational safety and health for its employees, maintaining strict vigilance at all times. Regular occupational safety goals and controls are planned, and incidents are managed and prevented according to the “Incident Reporting, Investigation, and Analysis Procedures.” This involves reviewing current situations, modifying hazard identification processes, conducting risk assessments, and making improvements. Safety and health awareness is promoted through educational training and on-site self-management, with the aim of eliminating potential hazards and preventing occupational accidents.

Ruentex Materials adopts a “Three-Tier Management” system for safety and health. This hierarchical management model ensures a thorough examination of workplace safety and health conditions at each level. The “Three-Tier Management” system is structured as follows:

| First-Level Management | After starting and before finishing work each day, employees inspect their assigned area of responsibility. During shift changes, workers perform 6S handover inspections. Immediate corrections are made for manageable issues, and for issues that cannot be immediately addressed, the department manager is notified for assistance. |

| Second-Level Management | In-plant safety and health management personnel conduct daily safety and health inspections, maintain records, send e mail announcements, track deficiencies, and follow up on improvements. |

| Third-Level Management | Ruentex Group conducts unscheduled monthly inspections and evaluations based on the 6S assessment system. Department heads from each division perform monthly checks of their assigned areas and provide scores. These scores are then factored into the distribution of production performance bonuses. |

Ruentex Interior Design Disaster Classification and Reporting Process

| Disaster Classification | Description of Situation | Reporting Procedure |

|---|---|---|

| Level 1: Any form of deviation or abnormal phenomena, minor engineering obstacles | 1. Minor property damage (less than 100,000 NTD) 2. Minor engineering obstacles (no need to halt operations, no injuries) | Discoverer > Immediately notify the unit supervisor > Notify the Safety and Health Team within 30 minutes |

| Level 2: Minor injuries, moderate engineering obstacles, external interference | 1. Minor injury (one or more individuals injured and requiring hospitalization) 2. Property damage (up to 100,000 NTD) 3. Moderate engineering obstacles (partial halt of operations) 4. Neighboring property damage Discoverer > Immediately notify the unit supervisor > Notify the Safety and Health Team within 30 minutes > Notify the Vice General Manager within one hour > Notify the General Manager within two hours | Discoverer > Immediately notify the unit supervisor > Notify the Safety and Health Team within 30 minutes > Notify the Vice General Manager within one hour > Notify the General Manager within two hours |

| Level 3: Any work safety accident, severe engineering obstacles, personal injury or death, property damage | 1. Serious injury or fatality 2. Three or more people injured 3. Property damage (greater than or equal to 300,000 NTD) 4. Severe engineering obstacles (immediate halt of operations) 5. Fires | Discoverer > Immediately notify the unit supervisor > Notify the Safety and Health Team within 15 minutes > Notify the General Manager within 30 minutes |