In recent years, Ruentex Development has continuously introduced innovative construction methods, setting new benchmarks in the construction industry. With a commitment to strict quality standards and rapid delivery timelines, the company focuses on planning premium residential and commercial real estate projects in prime locations. Through vertically integrated professional services, Ruentex Development aims to achieve the highest level of customer satisfaction, positioning itself not only as a leader in innovation but also as a “value-creating” team that maximizes the added value for both land and residents.

To ensure consistent construction quality, Ruentex Development provides a comprehensive range of services. In terms of materials, all masonry materials used in its projects are developed by its subsidiary, Runtex Materials Co., Ltd. This subsidiary is dedicated to advancing innovative and sustainable masonry materials. Many of its products have received Green Building Material Label certificates, LCBA Low Carbon Building Material Certification, and certificates of excellence for construction methods and product evaluations. Additionally, the company collaborates with Japanese firms to incorporate environmentally certified wood products into its projects, contributing to environmental sustainability.

In terms of construction, all construction projects are undertaken by subsidiary “Ruentex Engineering & Construction Co., Ltd.,” which has received the National Quality Award and multiple other recognitions. Ruentex Engineering & Construction Co., Ltd. possesses professional pre-cast technology, a strong R&D team, and multiple patented technologies, creating brand differentiation between Ruentex Development’s projects and competitors. It is one of the few professional construction companies in Taiwan that can comprehensively integrate all aspects of construction engineering. Ruentex Engineering & Construction Co., Ltd. has also obtained international certifications including ISO9001, CNS45001, ISO45001, ISO14064, and ISO14067. In addition to becoming the first construction company to receive the National Quality Award, it has also repeatedly won the Executive Yuan Public Works Golden Quality Award, Excellent Construction Industry Award, National Excellence Construction Award, and other recognitions for construction quality.

In terms of interior design, Ruentex Development’s subsidiary “Runtex Interior Design Inc.” is also the preferred choice for customers. It has repeatedly won awards from the TAIWAN GOOD DESIGN AWARD. It has been ranked “No. 1 in Building Renovation and Interior Design Industry” in the China Credit Information Service’s TP5000 Taiwan Large Enterprise Rankings for four consecutive years. Using “Five Senses and Six Perceptions” as important reference indicators in design, focusing on aesthetics, health, functionality, safety, peace of mind, and service, these are embodied in aspects such as Indoor Air Quality (IAQ), Indoor Environmental Quality (IEQ), and Indoor Environmental Health (IEH), allowing customers to use their five senses to experience the details of design and construction, making spaces more ingenious and human-centered.

Adhering to the philosophy that “houses are meant to take care of people, not the other way around,” Ruentex Development is committed to providing safe and high-quality building products that offer consumers peace of mind.

Integrated Planning

Ruentex Development has been in operation for over 40 years, applying its accumulated architectural engineering experience and proud construction philosophy. The company has developed a comprehensive structural system combining foundation piles, isolation pads, continuous hoop reinforcements, and spiral column stirrups. This system integrates various elements of safety, such as earthquake isolation, shock absorption, flood prevention, and fire protection, which Ruentex refers to as “Safety Engineering.” Additionally, the company incorporates “Comfort Engineering,” which uses green construction methods and eco-friendly, energy-saving materials; “Waterproof Engineering,” which ensures stringent standards for waterproofing with a unique industry-leading 20-year warranty on both waterproofing and structure; “Hygiene Engineering,” focusing on safeguarding the health of homes; “Smart Engineering,” which controls all aspects of community life with advanced technologies; and “Green Energy Engineering,” with provisions like electric vehicle charging stations in parking areas. These elements collectively establish Ruentex as a leader in safe, health-conscious residential innovations.

Construction

Conduct site inspections to check the construction quality of contractors:Throughout the construction process, environmental monitoring is performed at each stage, and site inspection frequency is supervised and documented according to regulations. Inspection records are documented on a project-by-project and personnel basis on the construction team’s high-level inspection webpage, ensuring that inspections are conducted frequently. Issues identified during inspections are promptly reviewed, corrected, and coordinated, with follow-ups to track project execution.

Construction Traceability Record:Each of our projects includes a “construction history,” which serves as an important proof of material quality provided to customers during the handover. The history includes details such as third-party testing reports, the types and frequencies of tests, and sample inspection standards (e.g., radiation-free steel bars, chloride content in concrete, tensile strength of steel bars, concrete compressive strength, steel bar coupler pull tests).

Electricity saving and energy/carbon reduction

Product & Service Description

- All lighting fixtures are equipped with LED energy-saving lamps. In public areas such as elevator lobbies and parking spaces, infrared sensors are used for automatic on/off control, and unnecessary lighting can be remotely controlled from the control room to save electricity.

- New construction projects reserve installation positions for electric vehicle charging pipes and cable racks during the initial planning stage, and have developed an inverted installation method for electric charging stations, increasing pedestrian safety and avoiding damage to parking garage floor waterproofing, providing more convenient and cost-effective installation options to enhance residents’ willingness to use electric vehicles.

- Energy-efficient variable frequency equipment is used to adjust operation frequency based on demand, along with detection devices to control the operating time of fans and ventilation systems, significantly reducing unnecessary energy waste

Improving the safety and convenience for residents.

Product & Service Description

- The building is equipped with automatic generator sets. When a power outage occurs, the generator will start, providing users with emergency power for elevators, water heaters, refrigerators, and other equipment.

- The water heater includes a forced exhaust function that directs the exhaust gases produced by gas combustion, such as carbon monoxide from incomplete combustion, outside through the piping, ensuring indoor air safety.

- The indoor emergency stairwells in the building are designed with positive pressure systems to prevent smoke from entering in the event of a fire, ensuring a safe escape route for all residents.

Pandemic Prevention Design

Product & Service Description

- Garbage Processing Room with Pandemic Prevention Design: Equipped with a sensor-operated switch, handwashing station, and hand dryer, making it easy for residents to clean their hands after disposing of waste.

- The design incorporates floor-specific exhaust systems, ensuring that waste gases are directly vented outside from each individual floor without sharing pipelines, thus preventing vertical gas diffusion between floors.

- Reserved ducts are provided to facilitate the addition of energy recovery ventilation, allowing continuous air circulation between indoor and outdoor environments.

Accessibility Design Considerations

Product & Service Description

- Barrier-free threshold design allows elderly family members and even disabled wheelchairs to pass through easily and comfortably, avoiding tripping injuries from thresholds.

- Bathroom grab bars: Considering the needs of residents, reinforced metal plates are embedded within the bathroom walls for secure installation of safety grab bars.

- Equipped with constant-temperature and humidity-controlled cold storage, featuring a sensor-activated intake for enhanced convenience and hygiene.

Convenient maintenance design and support

Product & Service Description

- Allows large furniture to be directly transported via the elevator, reducing the need for hoisting.

- Easier repair solutions.

- Videos covering various building types and home scenarios are available online to help residents address basic issues and troubleshoot equipment problems.

According to a 2021 International Energy Agency report, the building sector accounts for approximately 38% of global greenhouse gas emissions. Greenhouse gas emissions throughout the building lifecycle include both “operational carbon emissions” and “embodied carbon emissions.” Operational carbon emissions during the daily use phase account for approximately 28%, while embodied carbon emissions during construction and renovation/demolition phases account for approximately 10%. In response to Taiwan’s 2050 net-zero emission pathway and strategy, it is projected that by 2050, 100% of new buildings and 85% of existing buildings will need to be transformed into “near-zero carbon buildings.”

To reduce energy consumption and carbon emissions in buildings, Ruentex Development has made “green building” and “environmentally friendly materials” key design elements. This approach aims to reduce energy use and carbon footprint, optimize the utilization and management of buildings and resources, and improve the quality of both indoor and outdoor environments, thus minimizing negative environmental impacts and contributing to sustainable development. Over the past decade, all of Ruentex Development’s buildings have been designed to meet the Silver-level Green Building Label standards. Starting from 2024, all new buildings by Ruentex Development will apply for green building certification, and all commercial projects will obtain intelligent building certification, with Ruentex Yucheng Office Building additionally applying for diamond-level intelligent building certification.

Precast Construction Method

Multi-Spiral Reinforcement Method

Aluminum formwork construction method

PCS Construction Method

A structural system composed of reinforced concrete columns and steel beams, where the beam-column connections in the structural system use steel-reinforced concrete composite joints. The application advantages include not only the benefits of general precast methods but also maximize usable space due to different structural design, with more attractive appearance than general precast components.

Compared to traditional SRC, it can reduce the use of high-carbon column steel and pre-cast beam-column connections, not only reducing construction interfaces but also significantly shortening structural construction periods. With smaller phased construction intervals, it can shorten the startup time for work item interfaces, reduce on-site construction work, and lower construction site carbon emissions.

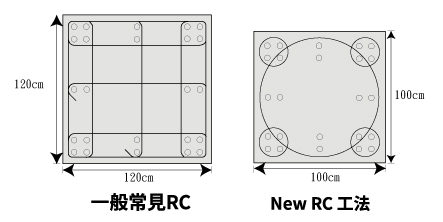

NewRC Construction Method