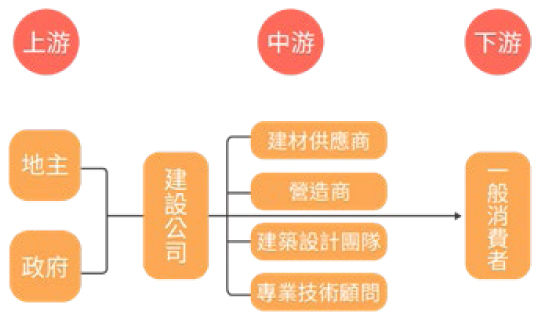

Ruentex Development’s industry value chain includes suppliers such as upstream landowners and midstream contractors, building material suppliers, architectural design teams, and professional technical consultants. Land sources are mainly obtained through land purchase, joint construction, urban renewal, and government tenders. For contractors, the main suppliers are Ruentex Development and Ruentex Engineering & Construction Co., Ltd., with Ruentex Engineering & Construction Co., Ltd. commissioning excellent contractors for joint construction.

For the shopping mall operations within the industry chain, changing consumer habits in recent years have shifted the focus to developing large suburban shopping centers or mixed-use malls. These commercial facilities require large tracts of land, typically located in suburban areas near urban centers. Site selection is mainly achieved through cooperation with government entities via BOT (Build-Operate-Transfer) projects or land use rights agreements, securing large plots of land adjacent to major transportation facilities or highways. The midstream process encompasses mall commercialization and leasing, including interior design, construction management, and the introduction of various brand tenants.

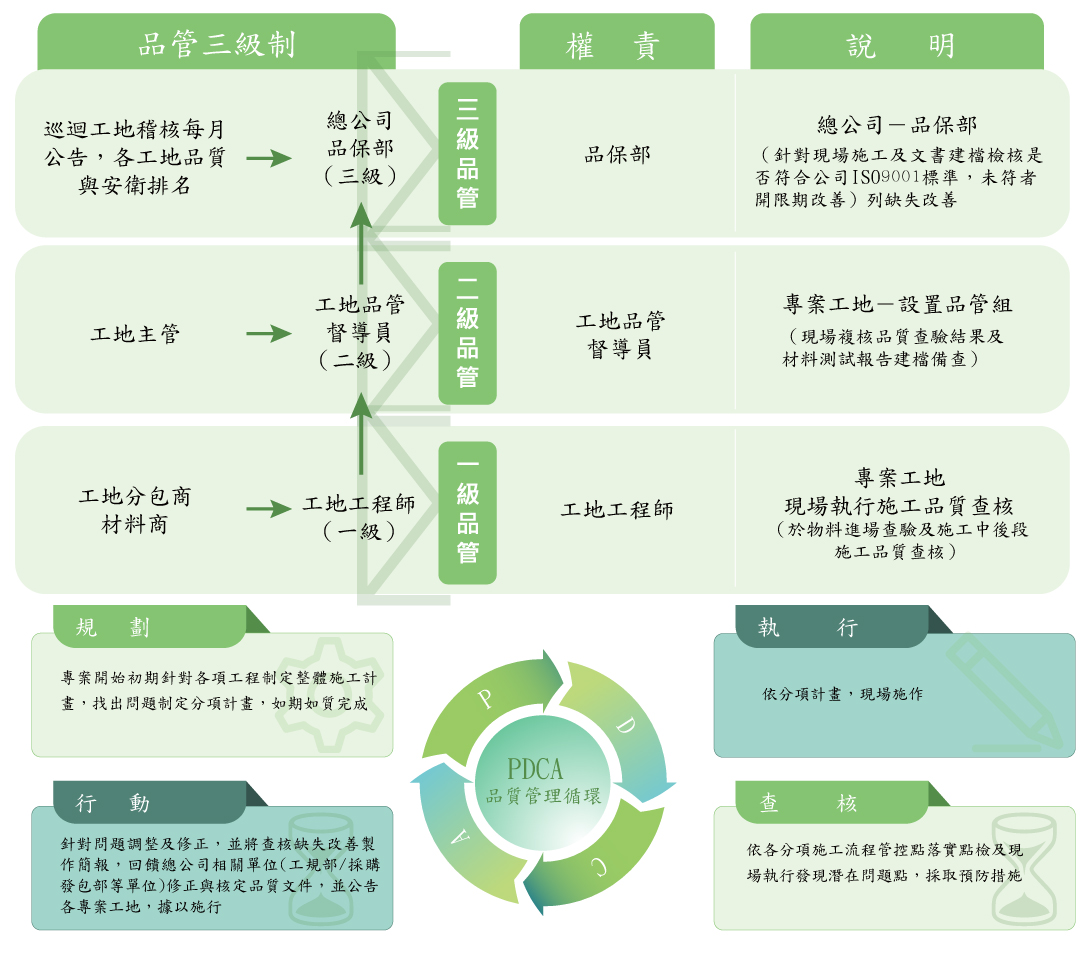

To achieve high efficiency and maintain stable engineering quality services, Ruentex Engineering & Construction Co., Ltd. has developed operational processes and system integration that differ from other construction businesses in the industry. Through precise planning and accurate construction, it provides customers with more comprehensive and complete design planning. Ruentex Engineering & Construction Co., Ltd., pre-cast factories, and their engineering sites have all established a three-tier quality control system and passed annual verification of the “ISO9001 Quality Management System” to ensure quality management at factories and engineering sites.

In addition to continuing to follow ISO 9001 standards annually for construction quality, they also utilize a Plan-Do-Check-Act (PDCA) management cycle. Internal reviews and effectiveness tracking are conducted through monthly construction meetings, management meetings, and pre-construction project briefings to assess construction quality. The Quality Assurance/Occupational Safety and Health Department conducts irregular inspections to assist project sites in maintaining quality, ensuring construction excellence.

Quality Management Measures

| Contract Signing Period | Before signing the contract, provide the contractor with the company’s internal construction standards or inform them of construction requirements, explaining the company’s expectations for quality, progress, and construction standards. |

| Preparation for the Early Stages of Construction | Hold a daily coordination meeting (morning meeting) to coordinate the use of trades, space, workflows, and materials, aiming to maximize efficiency and minimize conflicts and disruptions between different tasks. |

| Construction Stage Inspection | During contractor construction operations, colleagues follow plans/drawings and adopt mobile management at construction sites, conducting quality inspections on contractors’ construction work. Any discrepancies with drawings are immediately corrected and improved. |

| Review in the Late Stages of Construction | Hold a construction meeting every afternoon to review the quality, quantity, safety, and interface issues between different trades completed that day, to better plan the next day’s work. |

| Education and Training | Improve the knowledge, skills, and awareness of quality and safety for both employees and contractor personnel. |

Ruentex Development continues to maintain good cooperative relationships with suppliers, working together to achieve sustainable business goals. Through institutionalized supplier evaluation mechanisms, we carefully select qualified suppliers to ensure their products and services meet quality, environmental, and safety standards.

In the future, we will continue to refine supply chain management processes, working with suppliers through fair and open evaluation systems and transparent criteria to build a responsible supply chain and create a beautiful, sustainable life together.

Contractor Site Safety and Health Regulations (ESG-related items)

| Aspect | Evaluation Key Points |

|---|---|

| Corporate Governance | No outstanding payments to subcontractors, no requests for bill discounting Integrity in business operations: Strict prohibition of commissions and improper relationships |

| Social Responsibility | No employment of illegal workers; working hours and compensation must comply with government regulations; adoption of occupational injury prevention measures |

| Environmental Aspects | Local procurement: Use of materials and equipment that meet energy-saving, water-saving, and carbon emission reduction requirements Legal disposal of waste and prevention of environmental pollution (air, noise, wastewater, roadways) |